CHP Plant System High Temperature Pipe Leak Repair

An automotive safety supplier in the United Kingdom sought a live leak repair method for a leaking high temperature pipe joint in their on-site CHP Power Plant, wanting to avoid a system shutdown whilst a replacement part was fitted.

Site Automotive Safety Supplier Factory

Location West Midlands, UK

Pipe Type High Temperature

Repair Type Live leak repair

Products Wrap & Seal Pipe Burst Tape, SylWrap HD Pipe Repair Bandage

Pipe Defect

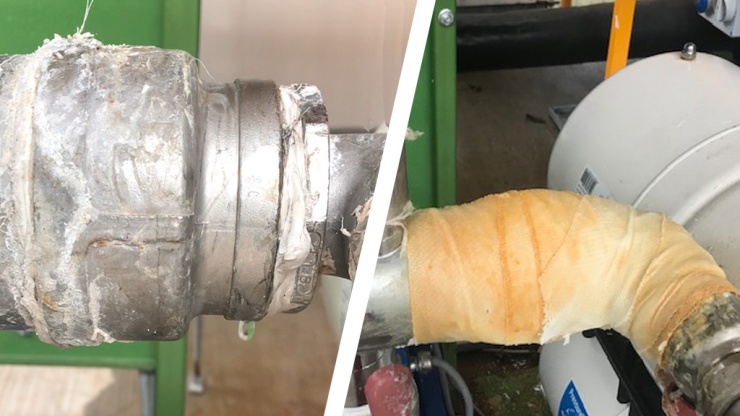

The CHP system was located in an on-site power plant at the automotive safety supplier’s factory. Although not a major leak, enough water was escaping from an elbow to be a concern as it seeped onto other parts of the CHP system, including motors and gas tanks located underneath the pipe.

CHP systems are put in place to increase energy efficiency and drive down costs. They do this by making use of the heat which would otherwise be wasted when generating electrical or mechanical power. A CHP system typically reduces energy bills by 20 percent and carbon emissions by 30 percent.

If a CHP Plant is not running efficiently, then these savings are lost. The automotive safety supplier was therefore keen to find a live leak repair solution for the pipe. To shut the CHP Plant down for a repair or replacement would have meant a highly disruptive interruption to the site’s power supply.

There were two complications with the repair. The leak’s location on an elbow joint ruled out a pipe repair clamp. Any repair method also had to be temperature resistant to 120°C to be effective within the CHP Power Plant system.

SylWrap Solution

As the CHP system would not be turned off for the repair, it was decided to use a SylWrap Universal Pipe Repair Kit suitable for fixing live leaks. A Kit was delivered to the automotive safety supplier for their staff to carry out the repair.

Wrap & Seal Pipe Burst Tape was used to seal the leaking pipe. Wrap & Seal is a waterproof repair tape made from self-fusing silicone which stretches by 300 percent, forming a solid rubber band to seal highly-pressurised leaks.

Once the leaking elbow had been repaired with Wrap & Seal, SylWrap HD Pipe Repair Bandage was applied over the top. SylWrap HD is a water-activated composite wrap which sets rock hard in minutes, creating a protective shell to pipework and reinforcing the initial repair.

Repairs made with Wrap & Seal and SylWrap HD are pressure resistant to 30 bar and temperature resistant to 200°C. The heat of the CHP Plant did cause SylWrap HD to cure with a red tinge; if the automotive safety supplier wished for the pipe repair to appear uniform with the rest of the system in future, then SylWrap HD can be painted.

Outcome

The automotive safety supplier contacted Sylmasta afterwards to say how pleased they were with the repair which was an instnat success, noting how quickly and effectively it worked in what had at first appeared challenging circumstances.

Follow Up

With the automotive safety supplier operating several sites across the UK, Sylmasta recommended that they take stock of a SylWrap Pipe Repair Contractor Case for fixing future problems not just in CHP Plants, but also to other pipework.

Each Case contains enough products to make up to six permanent live leak repairs at a cheaper cost than purchasing individual kits. The Case can be easily stored on-site, enabling companies with facilities like the automotive safety supplier to take charge of their own pipe repair and maintenance, rather than relying on contractors or outside management.

Products Used

Wrap & Seal Pipe Burst Tape

Self-fusing silicone pipe repair tape, seals live leaks, temperature resistant to 200°C

SylWrap HD Bandage

Water-activated wrap sets rock hard to reinforce, protect and strengthen repairs

Universal Pipe Repair Kit

Wrap & Seal and SylWrap HD can be purchased together in a Universal Pipe Repair Kit

Pipe Repair Contractor Case

Easy-to-store case with everything needed to make up to six emergency pipe repairs

Related Case Studies

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com